environmental strategy

Gossi Park & G.James are committed to environmental awareness and aluminium recycling practices.

The business is committed to supporting sustainable practices and environmental stewardship within the glass and aluminium industry.

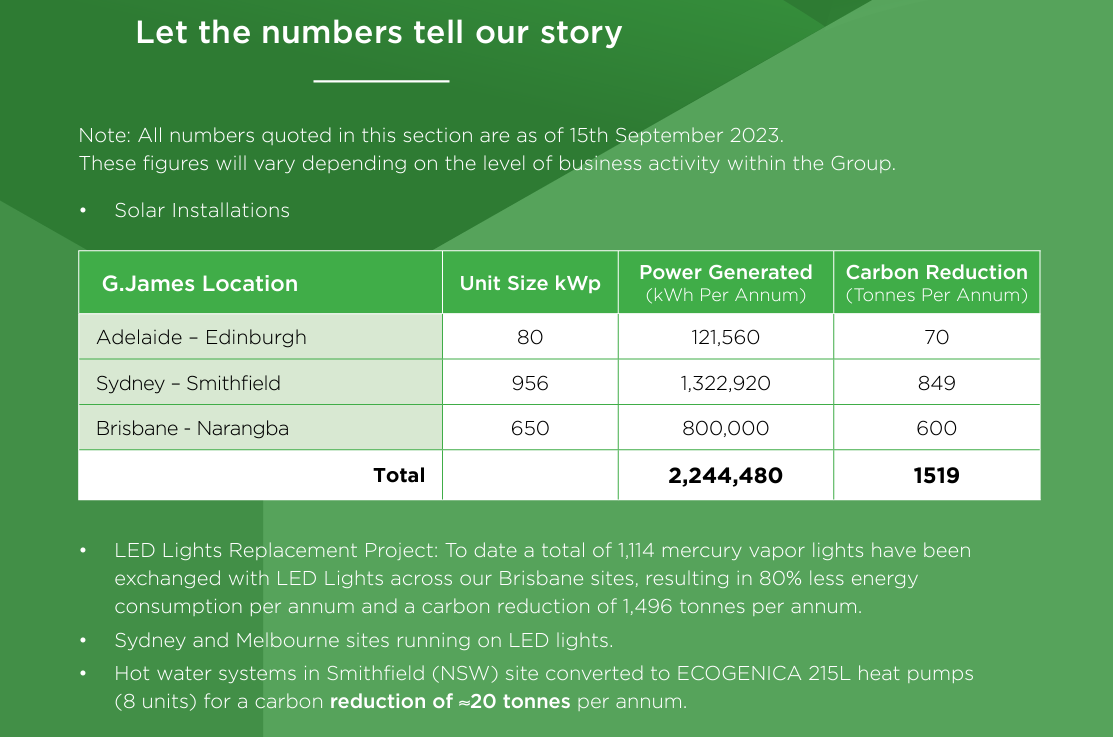

Where possible, we invest in state of-the-art technologies and equipment to minimise waste generation and optimise our output. Emphasising the actions of Reduce, Recycle and Review, we will continuously strive to improve our production methods and raw material consumption to reduce our overall environmental impact and preserve our natural resources for future generations.